-

Products

Products

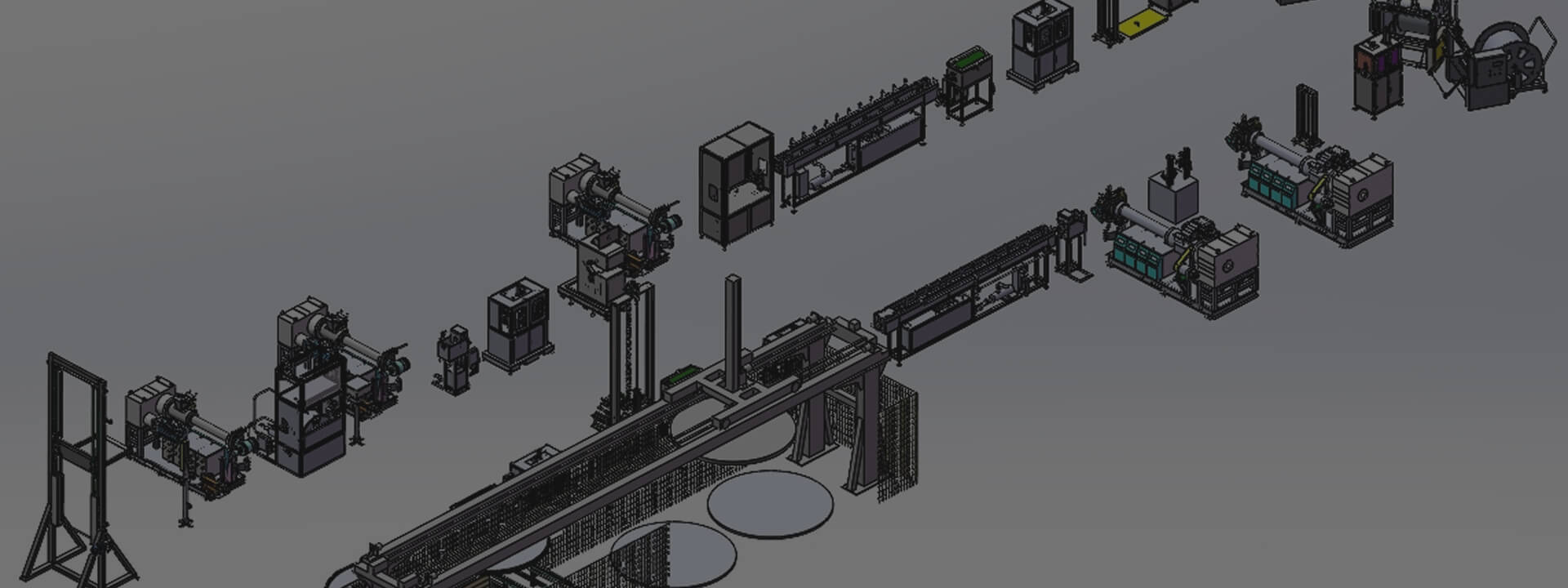

- Hose production line host products

- Inner and external rubber extrusion production lines and automation control, data processing

- Rubber tube shaft core cutting, connection, and vulcanization production line

- TPX peeling, crushing and recycling line

- Rubber hose TPX online winding, core removal, pressure testing, detection, and packaging production line

- Special shaped rubber tube shaping oven (natural gas)

- Auxiliary equipment products for rubber hose production line

-

Phone

-

Email

-

WeChat

Solution

Air conditioning hose project

Basic process route:

Core rod preparation → Inner rubber extrusion → Braiding → Outer rubber extrusion → Rubber tube vulcanization → TPX peeling and crushing → Core removal inspection, finished product packaging

Hydraulic (brake) hose project

Basic process route:

Core rod preparation → Inner rubber extrusion →Braiding (double-layer) → Outer rubber extrusion → Rubber hose vulcanization → Core detachment inspection, finished product packaging

Coreless (winding, braiding) hose project

Basic process route:

Internal rubber extrusion → Online winding and braiding → External rubber extrusion → Online cutting → Rubber hose vulcanization → Hose washing, inspection, and finished product packaging

High voltage steel wire hose project

Basic process route:

Core rod preparation → Inner rubber extrusion → Steel wire braiding → Outer rubber extrusion → Rubber hose vulcanization → Water cloth or plastic coating peeling → Core detachment inspection, finished product packaging

Nylon composite extruded hose project

Basic process route:

Nylon composite (three-layer) extrusion → Knitted reinforcement → Smooth surface, corrugated tube → Inspection, finished product packaging